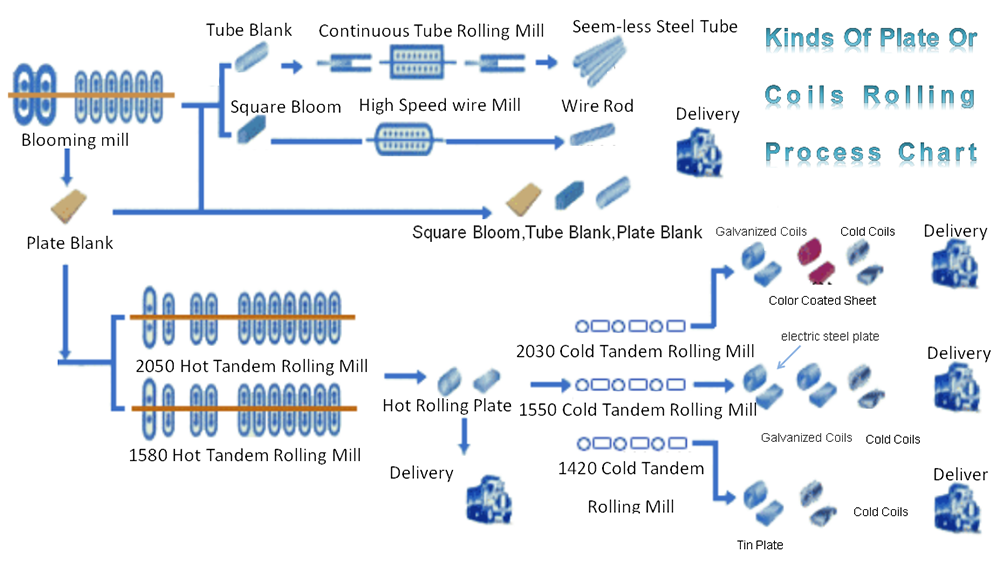

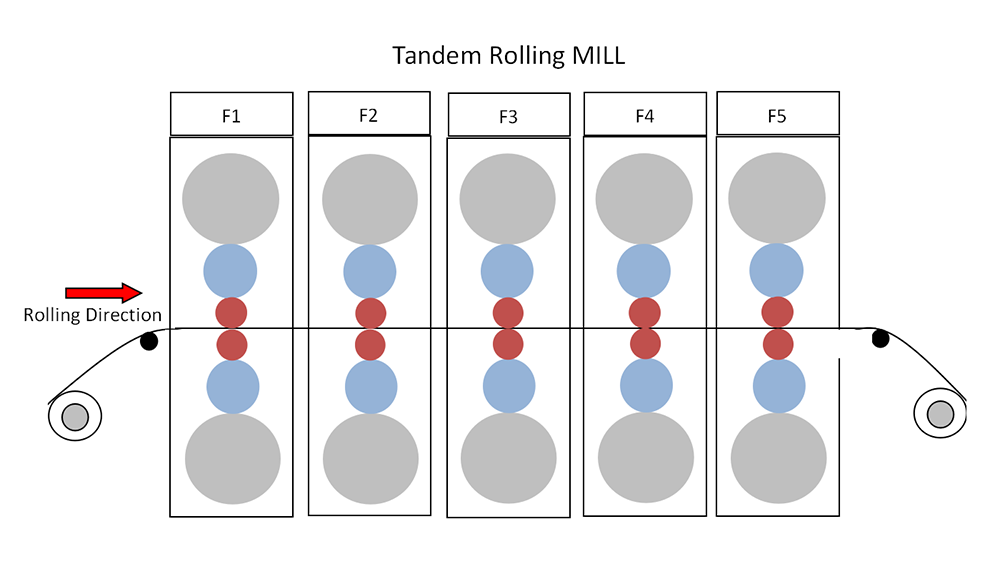

Left picture is normal rolling process flow chart. We can produce galvanized plate, tin plate,automobile plate and aluminum plate with differernt raw material and tandem rolling mill. Because the roll is the one most important component of mill, the quality of roll becomes the key factor of quality of all kinds coils.Beside it,because of different application of kinds of coils,the requirement of roll is also different which include: material, hardness, CHD, shape design and so on. We hope you can know the roughly process based on the flow chart.