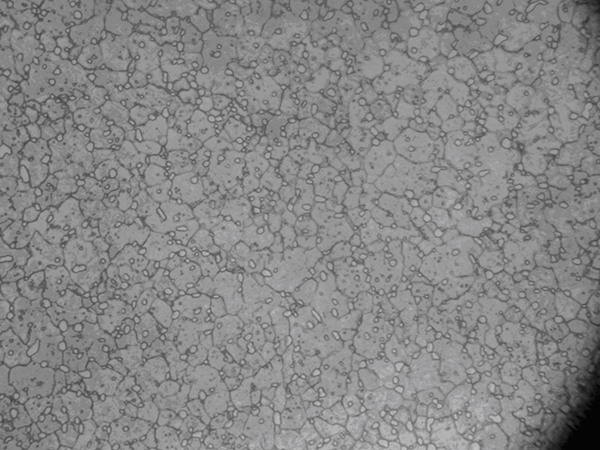

| Cr2 | Mainly used 4HI Mill,produce copper plate and appliance. Surface hardness control between 70~78HSD,rigth now it just used in the small/normal size factory.It could meet basic needs of milling,and the matched work roll material should be Cr2 and Cr3.The change circle can reach 8000t. |

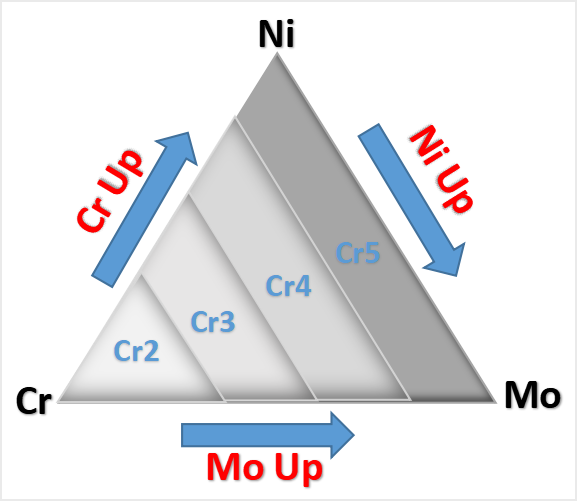

| Cr3 | mainly used in 4HI Mill and 6HI tandem Mill,produce aluminum and tinplate with better anti-wear and grindablity. The surface hardness required 65~75HSD and the change circle can reach 10000t. |

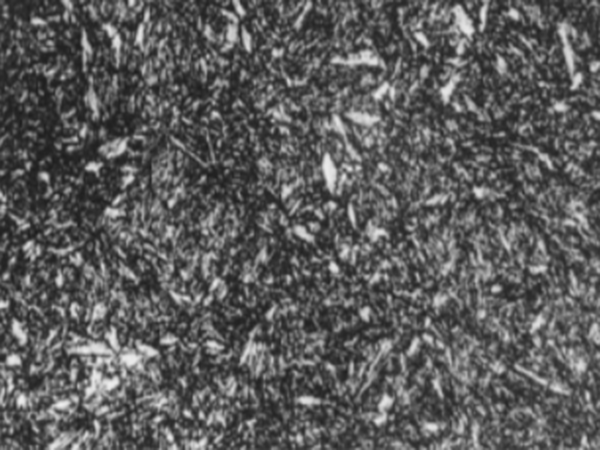

| Cr4 | It is the advanced material version for the automobile line and appliance line whose hardness required 70-78HSDe.It appears higher wear resistance and hardness retaining. The grindablity is same as Cr3 material and the fatique layer is less than Cr3. So the change circle can reach 15000t. |

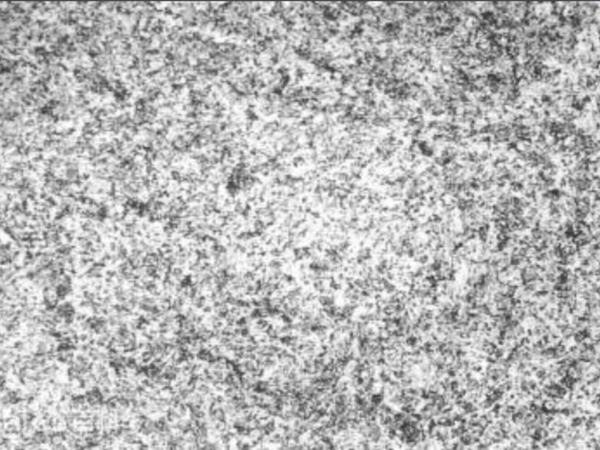

| Cr5 | It's the favorite choice of morden factory.It most used in the automobile line and silicon line because of unique anti-accidental, normal grindablity ,the best high roughness retaining and the least fatique layer.The change circlr can reach 18000t. |

| Cr5A | The material is founded on Cr5 with different manufacture process.It use big inductor for whole roll body heating rather than differertial temperature quenching. The quenching process is strictly controlled and the hardening depth is bigger that original one. The biggest advantage is longest lifetime. |

Cr2 500x

Cr3 500x

Cr4 500x

Cr5 500x